PALLETIZER ROBOTS

RoTeg Palletizer Robot

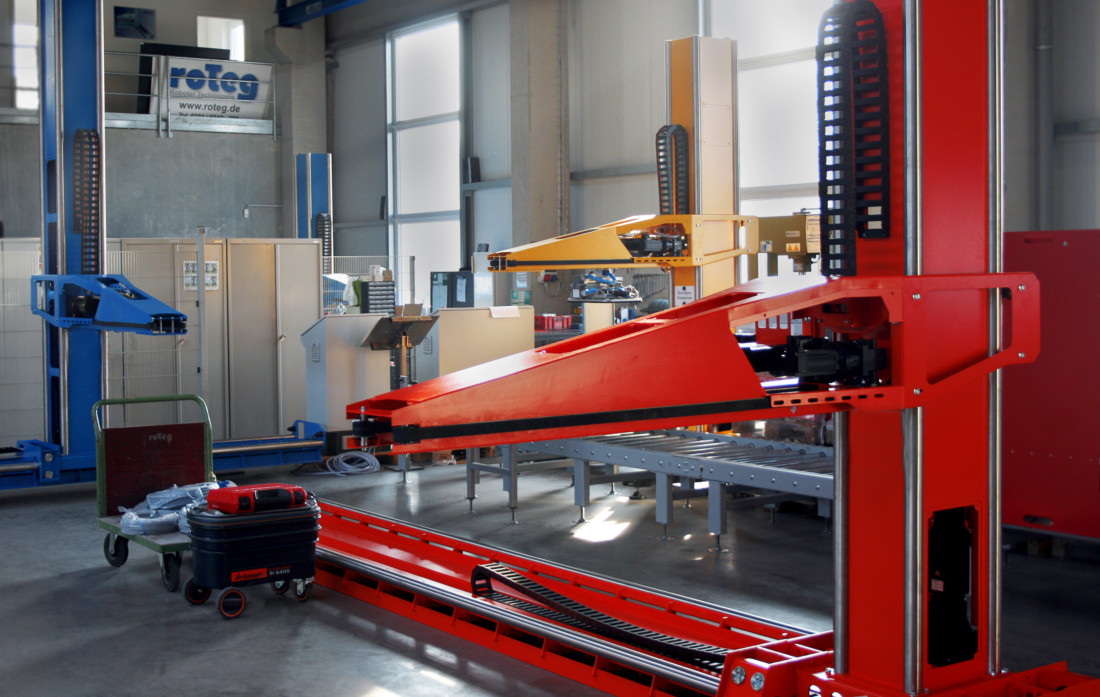

The RoTeg Palletizer Robot is a cartesian robotic system proven in many applications, it’s excellent for palletizing and depalletizing.

The robot was designed by roTeg in 1996 and over time it has become one of the most versatile systems on the market.

Nowadays it has become a consolidated system: it consists of the roTeg industrial robot as the main system, and multiple clamp options, as well as components adapted for the transport of the product and of the pallets, roller conveyors for pallets and very easy to use.

The advantages are listed quickly:

- Modular construction

- Controlled by PC

- Servomotors without maintenance.

- Touch screen created with an easy-to-use format

- CAN-Bus

- Grip solutions for many applications.

- Standard interface

RoTeg Palletizer Robot

The RoTeg Palletizer Robot is a cartesian robotic system proven in many applications, it’s excellent for palletizing and depalletizing.

The robot was designed by roTeg in 1996 and over time it has become one of the most versatile systems on the market.

Nowadays it has become a consolidated system: it consists of the roTeg industrial robot as the main system, and multiple clamp options, as well as components adapted for the transport of the product and of the pallets, roller conveyors for pallets and very easy to use.

The advantages are listed quickly:

- Modular construction

- Controlled by PC

- Servomotors without maintenance.

- Touch screen created with an easy-to-use format

- CAN-Bus

- Grip solutions for many applications.

- Standard interface

RoTeg development

The new technology for Cartesian axle systems.

The incentive to develop the roTeg robot was easy handling and robustness. After an extensive series of tests and trials, a system was found that meets all the requirements to achieve these objectives. The system is based on linear movement guided by high-strength stainless steel tubes. Sliding on these guides we have a series of profiled bearing that are coated with doubly elastic materials. This system guarantees silent operation. Multiple coating bearings have proven to be extremely robust, especially in problematic environments. Dust, paint, adhesive products and also broken glass won’t damage the system. It shouldn’t be overlooked that the elastic coating of the bearings has an effect on the positioning accuracy of the robot. The resulting tolerance is +/- 1 mm, more than enough for all handling tasks related to palletizing.

RoTeg development

The new technology for Cartesian axle systems.

The incentive to develop the roTeg robot was easy handling and robustness. After an extensive series of tests and trials, a system was found that meets all the requirements to achieve these objectives. The system is based on linear movement guided by high-strength stainless steel tubes. Sliding on these guides we have a series of profiled bearing that are coated with doubly elastic materials. This system guarantees silent operation. Multiple coating bearings have proven to be extremely robust, especially in problematic environments. Dust, paint, adhesive products and also broken glass won’t damage the system. It shouldn’t be overlooked that the elastic coating of the bearings has an effect on the positioning accuracy of the robot. The resulting tolerance is +/- 1 mm, more than enough for all handling tasks related to palletizing.

PALLETIZER ROBOTS

Palletizing robots are used to eliminate the effort of the operator in the palletizing process and increase the speed of the process.

Efficiente

Affordable

Simple

Roteg palletizer robot

- Precision laser cutting

- Made in Germany

- Robust and durable design

- Four servo axes

- PC control with CAN bus technology

Depalletizer Robot DERO I

- Layered deposit

- 3-axis robots

- Series 800 for Euro pallets

- Series 1000 for industrial pallets

- Prove control technology