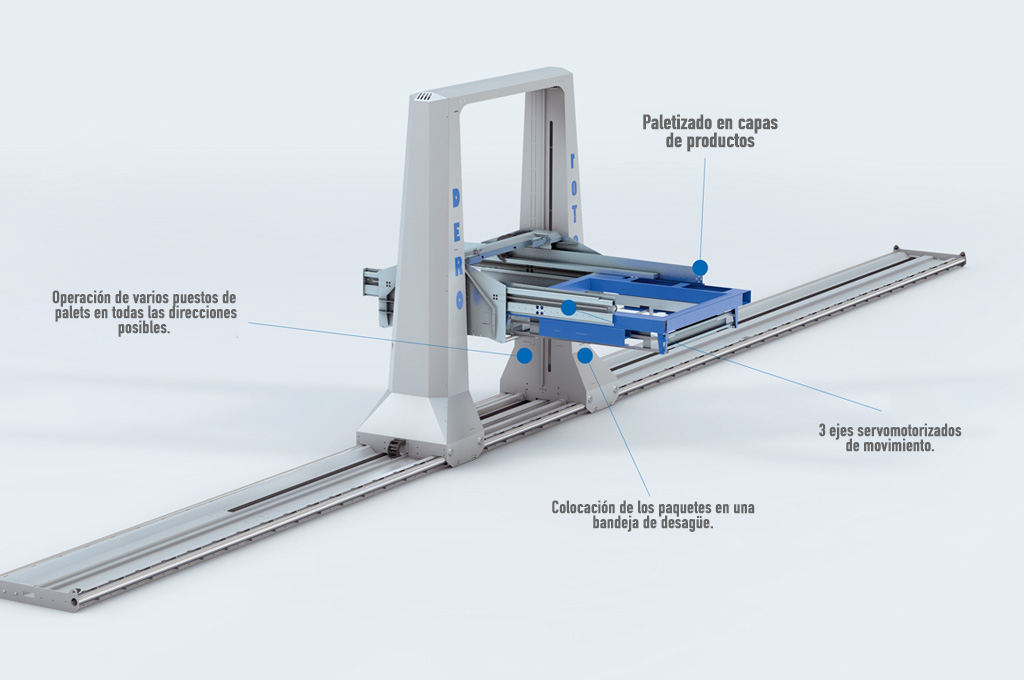

DERO II Depalletizer

Designed for depalletizing products such as bottles, cans or bottles in the pharmaceutical and food industry, the DERO II Depalletizing Robot is characterized by its flexibility and reliability. It can be used for different product diameters and can be used for several pallet spaces.

3-axis principle

With its three axes, the robot positions the products and centers them on an intermediate table and at the same time removes the separator. The DERO II depalletizing robot works with a perimeter clamp, which initially encloses the upper level of the product and centers it with the clamp. The clamp pushes the entire product level to the intermediate table. Then the robot moves to the unloading position and the clamp pushes the product on the table. When the clamp is raised, it picks up the separator and positions it in the separator discharge with a vacuum.

Diameter of the variable product

The DERO II depalletizing robot can even easily depalletize several package diameters, since the centering frame of the gripper system encloses the entire layer. Because the fixation works without external pressure, the material is handled very smoothly.

Robust and low maintenance construction

In the development of the system, the use of low maintenance components was considered of increased importance. Thus, the three axes are driven by maintenance-free servomotors. Stable and simple kinematics guarantee minimum maintenance costs.

Do you need a budget?

Contact Us