ROTEG Palletizer

Safe production that respects the environment and requires an optimal use of all available resources. roTeg has designed its compact robotic cell for efficient production.

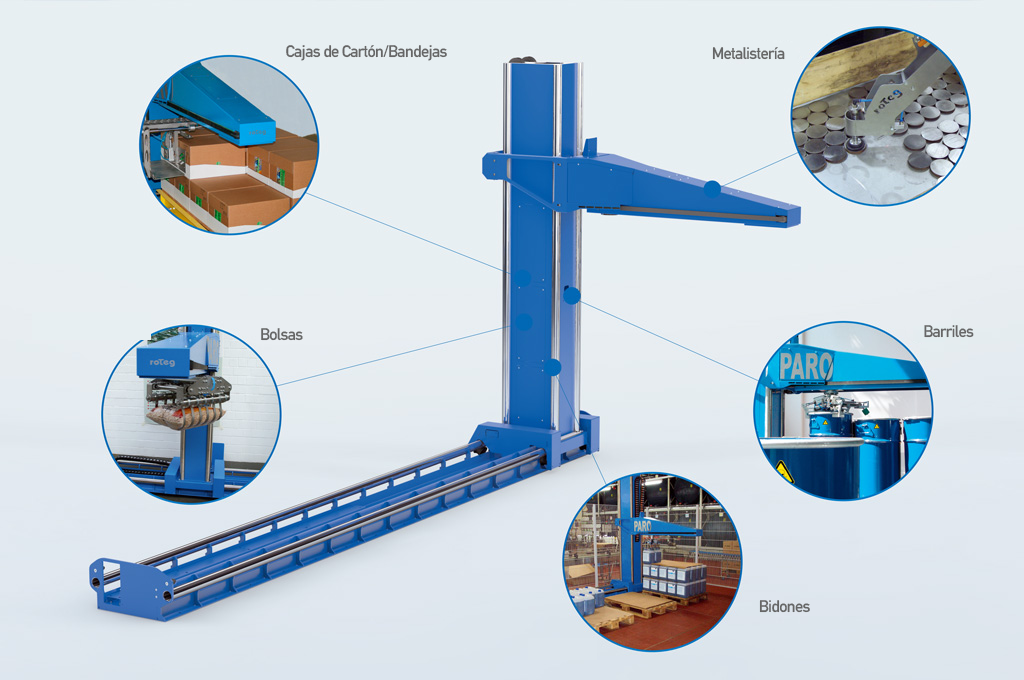

ROTEG palletizing system

A roTeg robotic cell consists of a four-axis robot as a central component, many grip systems and associated components for transporting boxes, roller conveyors for feeding and evacuating pallets, as well as numerous control and detection components.

An incredibly talented robot

A multifunction clamp mounted on a standard DIN flange is sufficient for palletizing or depalletizing, containers, boxes, buckets, plastic containers or coatings at the same time. Many roTeg grip systems are patented or protected by a utility model, such as the boat clamp, the eccentric sub-clamp for buckets or various vacuum grip systems.

Space saving and easy to use

Robust and simple design, the robots of depalletization and palletization can be used even in productions with very low ceilings and limited space. Also different palletising heights are easily achievable.

Modular and extensible

Particularly practical is the free grip space design, which allows to place several pallets in series. Each robot can be adapted to ten or more pallet locations or reconstructed or adapted by extending the elevation axis to the desired palletizing height.

Speed and flexibility

RoTeg developed the DERO I and II depalletizer robots, which are widely used in the food and pharmaceutical industry and are characterized by the same great flexibility as the RoTeg palletizer robot.

Do you need a budget?

Contact Us